The concept of a retail warehousing comes from the continued decline of available warehouse space in the United States. According to the Wall Street Journal, retailers throughout the country are experiencing a shortage of available warehouse capacity. The effects of less warehouse capacity causes a lot of issues for retailers, from an inability to meet ecommerce demand to longer delays in order fulfillment. Your order fulfillment process is the foundation. Things are changing though, a new trend is occurring as developers across the country are focusing on retail-to-warehouse conversions, and supply chain leaders need to understand what a retail warehouse is and how it can impact profitability and productivity.

Less Warehouse Space Is A Major Problem

The fundamental problem associated with retail-to-warehouse conversions, also known as retail warehouses, stems from the massive growth of retail and the continued decline of warehousing. We’ve already seen how ecommerce has effected malls throughout the United States, the ecommerce evolution is responsible for tens of thousands of closed stores. Big retail centers use to thrive and now, it’s difficult to not pass the remains of them on a trip to your local store. Today, retailers have to think outside the box as it pertains to their retail space. There’s a lot of benefits having retail warehousing in your supply chain.

Other retail structures that were left standing after the retailers closed up shop are also being repurposed for industrial uses, including a former Toys ‘R’ Us store (Wisconsin) that now remanufactures transmissions and Sam’s Club facilities are now distribution centers. With both commercial and industrial space available, there’s a lot of opportunities out there for companies to claim the space they need.

Retail Warehouses Converting To Meet Ecommerce Demand

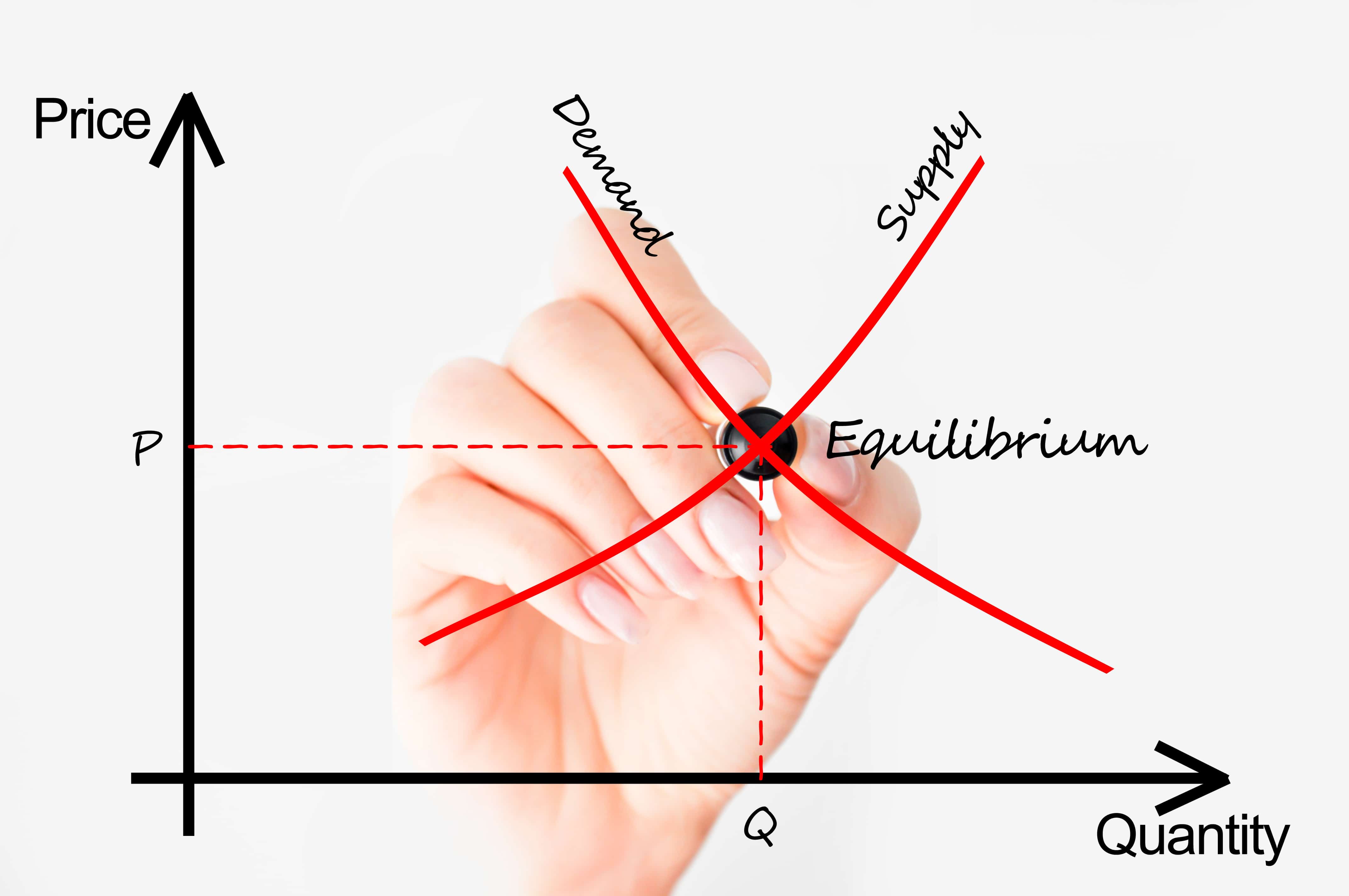

Retail warehouses come with a lot of perks for companies that are planning to use them for growing ecommerce demand. Retail spaces naturally possess the power of being available, this is why conversion projects are currently underway in markets that have high vacancy rates. Despite that, it won’t be easy getting these retail properties as the prices are fueling the demand.

Why target the retail space? There’s a number of different reasons why it makes sense to jump in. One of the biggest is the prime real estate space of these retail centers, such as busy intersections or highway interchanges. Every retail center is strategically placed in a specific area, some times it pays off, other times it doesn’t. Site access is another reason why retail centers are targeted. The giant big-box stores want backend docks and easy access for trucks, easy come, easy go. They also have what most retailers need, which are high ceilings and plenty of space. At the moment, there’s more retail space available versus industrial, that’s a weighing factor as well.

If you go back a decade or two, you’d find very few investing into retail centers. Today, it’s a growing trend and companies are making retail warehousing work.

Benefits Of A Retail Warehouse For E-Commerce Fulfillment

A retail warehouse is an excellent opportunity for companies looking to optimize their ecoomerce and expand their supply chain. There’s a wide range of benefits associated with retail warehousing, let’s have a look:

- These retail facilities give you a foundation to immediately build upon and leverage.

- Redevelopment of struggling urban areas, such as those where big retailers have left.

- More competitive advantages for omnichannel needs in your niche.

- Opportunity to obtain local and regional store distribution centers.

- Freestanding facilities offer dock doors, clear heights compatible with industrial use and lots of parking.

- Utilizing already established retail warehouses and retail centers.

Cons Of Converting Retail Space

- Malls have a lot of things you don’t need, hence escalators, individual space.

- May not be exactly what you need.

- May have higher costs than initially thought.

- It is a risk.

Retail warehouses are going to be the next way companies expand warehouse space. The industry will feel the effects as more companies look for warehousing space and turn to former retail spaces for utilization.

Now, being able to take advantage of retail warehouses are going to require expansions, from management platforms to integrations of existing platforms. If you’re planning on leveraging retail warehousing, it appears the time to act is now.